A tractor's suspension configuration plays a crucial role in operator comfort and overall productivity. Harsh vibrations from uneven terrain can lead to fatigue, back pain, and reduced concentration. A well-designed suspension mitigates these impacts, creating a smoother ride for the operator. This not only boosts comfort but also allows operators to focus on their tasks more effectively, ultimately leading to increased efficiency and productivity.

The ideal tractor seat suspension should include a combination of elements. These include the type of shock absorbers, the stiffness of the system, and the overall design of the seat itself. Additionally, adjustable features allow operators to personalize their seating experience, fine-tuning the suspension to match their individual needs and preferences.

Ultimately, investing in an optimal tractor seat suspension is a wise investment that can significantly improve operator well-being and boost productivity on the farm.

Truck Seat Solutions: Reducing Fatigue and Improving Safety

Long-haul trucking presents a unique set of challenges for drivers, with fatigue being one of the most significant. Prolonged periods behind the wheel can lead to drowsiness, reduced reaction times, and increased risks on the road. Fortunately, there are various truck seat solutions available that aim to mitigate these risks by providing enhanced comfort and support.

Customizable truck seats are designed to promote proper posture and reduce strain on the driver's body. Features like lumbar reinforcement, adjustable headrests, and breathable fabric help create a more comfortable seating environment. By minimizing discomfort, these seats can contribute to enhanced alertness and focus, ultimately reducing fatigue-related accidents.

In addition to comfort, some truck seats incorporate features that actively reduce fatigue. Vibrating massage functions here can help awaken the driver, while air suspension systems provide a smoother ride and reduce road vibrations. These innovations work in tandem to create a safer and more enjoyable driving experience for long-haul truckers.

By investing in truck seats that prioritize both comfort and fatigue reduction, trucking companies can demonstrate a commitment to the well-being of their drivers.

Operator Cab Comfort

A suitable forklift truck seat is essential for operator well-being. Prolonged time spent operating a forklift can lead to back pain, particularly due to the inherent oscillations present in this type of work. Ergonomic design are crucial for minimizing these risks and maximizing operator productivity.

A well-designed forklift seat should provide sufficient lumbar support to alleviate lower back strain. Customization in features like seat height, backrest angle, and armrests allows operators of different heights to achieve a comfortable and ergonomic working configuration.

Vibration control is another key aspect of forklift seating. Specialized suspension systems can effectively absorb vibrations transmitted from the forklift to the operator, reducing fatigue on the body.

In conclusion, prioritizing ergonomics and vibration control in forklift truck seating is vital for operator safety. By investing in seats that incorporate these characteristics, businesses can create a safer and more efficient work environment for their forklift operators.

Loader Seat Design: Built to Endure Demanding Conditions

When it comes to loader operator well-being, seat design is paramount. These machines operate in often rugged environments, subjecting operators to prolonged periods of vibration, shock, and temperature fluctuations. A well-designed loader seat must not only provide a comfortable seating experience but also offer vital security from these demanding conditions.

Modern loader seats are engineered with cutting-edge materials and technologies to meet these requirements. They often incorporate features like versatile suspension systems, lumbar support, and durable fabric upholstery. These elements work in tandem to minimize operator fatigue, improve awareness, and ultimately contribute to a more effective workday.

Mining Equipment Seats: Maximizing Durability and Support in Harsh Environments

In the demanding world of mining, equipment operators face extreme conditions day in and day out. Their well-being is paramount, and a crucial element in ensuring this is the quality of their seats. Mining equipment seats are designed to withstand relentless vibration, prolonged use in harsh environments, and the weight of operators performing demanding tasks. These seats must be built with durable materials like reinforced fabrics, high-density foams, and robust supports to ensure longevity and reliability.

- Advanced suspension systems are often integrated into mining equipment seats to minimize the impact of bumps, jolts, and uneven terrain.

- Thoughtful seat ergonomics play a critical role in providing operators with proper backrest for extended periods, reducing fatigue and the risk of musculoskeletal disorders.

- Features like adjustable armrests, headrests, and lumbar support allow operators to customize their seating experience for maximum satisfaction.

Manufacturers continuously innovate in this field, incorporating cutting-edge technologies such as breathable fabrics, temperature-regulating materials, and integrated heating and cooling systems to enhance the overall operator experience. By prioritizing durability, support, and operator well-being, mining equipment seat manufacturers play a vital role in creating safer and more productive work environments for those who operate heavy machinery in challenging conditions.

Construction Seats: Advanced Suspension for Precise Operation

Modern excavators demand accurate control. This is where the relevance of advanced suspension systems in excavator seats comes into play. A well-engineered suspension system minimizes vibrations and impacts transferred from the ground to the operator, creating a smoother ride. This boosts operational comfort, allowing operators to pay attention on tasks with greater precision.

Furthermore, advanced suspension systems can optimize the operator's capacity to control the excavator. By isolating vibrations and shocks, these systems provide a stable platform, guaranteeing that operators can perform complex maneuvers with confidence and success.

- Innovative designs in excavator seat suspension include hydraulic dampers, air springs, and active control systems. These technologies work together to filter the ride, providing operators with a comfortable and efficient working environment.

- Selecting an excavator with advanced suspension in its seats is a intelligent decision for any operator who values comfort and performance.

Shaun Weiss Then & Now!

Shaun Weiss Then & Now! Amanda Bynes Then & Now!

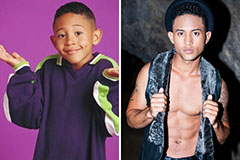

Amanda Bynes Then & Now! Tahj Mowry Then & Now!

Tahj Mowry Then & Now! Christina Ricci Then & Now!

Christina Ricci Then & Now! Jenna Von Oy Then & Now!

Jenna Von Oy Then & Now!